1. According to specific requirements, choose the structural form of the level gauge, including integrated, split, and liquid level transmitter.

2. Integrated is the most commonly used form, divided into two wire, three wire, and four wire systems.

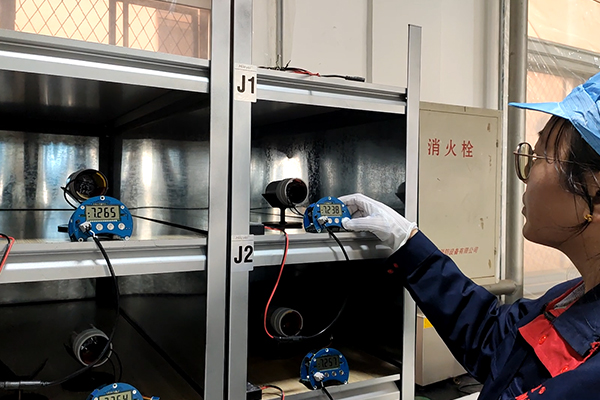

3. The split type level meter facilitates on-site observation of measurement values and has a wide range of signal output options.

4. For sealed containers, if the liquid evaporates greatly or fluctuates violently, it is recommended to choose a model that is one level larger than the actual range. For an actual 6-meter range, it is recommended to choose an 8-meter range level meter.

5. For outdoor applications in the north, if there is frost, choose a model with electric heating function.

6. Material level measurement is suitable for measuring particle and block material levels below 10 meters. It is recommended to use a radar level meter in situations with large dust and range.

7. For corrosive liquids, the liquid name should be clearly defined to select sensor materials that are suitable for their corrosiveness.

8. For explosion-proof locations, please choose a level meter with intrinsic safety and explosion-proof certification.

structure type

Integrated

split

liquid level transmitter

ultra-small blind zone liquid level transmitter

two-wire three/four-wire system

Media properties

Medium name

medium temperature

strong

volatility, large fluctuations

corrosion

material level

measurement range

power supply

Application places

Indoor

and outdoor

explosion-proof

Signal output

4-20mA

HART

MODBUS

PROFIBUS-DP

relay

ABOUT USDalian Hilevel Measurement and Control Technology Co., Ltd. is a high-tech enterprise dedicated to the research and development, production, and sales of ultrasonic level meters (liquid level meters, material level meters), radar level meters, and open ch

ABOUT USDalian Hilevel Measurement and Control Technology Co., Ltd. is a high-tech enterprise dedicated to the research and development, production, and sales of ultrasonic level meters (liquid level meters, material level meters), radar level meters, and open ch PRODUCTHilevel Measurement and Control strives for excellence in the production, manufacturing, and quality of products, with a complete set of production and testing process standards, striving for perfection in production, and leading equipment quality in the

PRODUCTHilevel Measurement and Control strives for excellence in the production, manufacturing, and quality of products, with a complete set of production and testing process standards, striving for perfection in production, and leading equipment quality in the SUPPORTTechnical support is one of our company's important services. We are committed to providing comprehensive technical support to customers, helping them solve technical problems and challenges encountered during the use of products or services.

SUPPORTTechnical support is one of our company's important services. We are committed to providing comprehensive technical support to customers, helping them solve technical problems and challenges encountered during the use of products or services.

CONTACT USHilevel Measurement and Control creates a brand with services and touches people's hearts with sincerity. You can contact us through the following ways

CONTACT USHilevel Measurement and Control creates a brand with services and touches people's hearts with sincerity. You can contact us through the following ways

split

split

(+86) 0411- 84646800

(+86) 0411- 84646800